Big savings of starch with the help of Voith's Papermaking 4.0 solutions – successful digitalization project with Saica

News General news

- Comprehensive Papermaking 4.0 package for PM 9 in El Burgo

- OnCumulus, OnView.MassBalance and OnEfficiency.Strength enable significant resource savings

- Saica plans to expand its digitalization strategy

The results are clear: Just a few months after Voith's comprehensive digitalization solutions were commissioned at PM 9 in El Burgo, Saica Group's investment in the Papermaking 4.0 package has already paid off. The Spanish paper manufacturer produces around 430,000 tons of paper per year at the facility, located around 25 kilometers from Zaragoza. At the end of 2020, the company decided to digitalize production. After a thoroughly positive experience with the digitalization of PM 4 in Venizel, France, Voith was awarded the contract to implement the project for PM 9, which includes OnCumulus applications and the two solution packages OnView.MassBalance and OnEfficiency.Strength.

"Voith has been a great partner along the digitalization journey in our mills. Our perception of Voith Paper as one of the main digital solutions provider is reaffirmed every day, and we are very glad with the cooperation with Voith over the last years. We have the full commitment of both companies, which makes us look forward to the next successful cases." (Fernando Carroquino, Industrial Director at Saica Group)

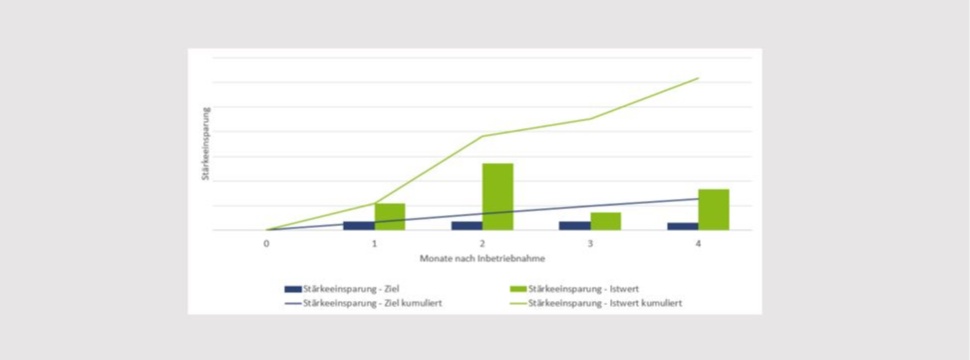

The main goal of OnEfficiency.Strength on a paper machine for container board is to reduce the consumption of starch without negatively affecting the strength properties of the paper. The solution uses virtual sensors as a basis on which innovative advanced process control is built. OnEfficiency.Strength has already proven a high benefit in several references and significantly reduced the product cost. At PM 9, too, the high potential of digitalization became apparent shortly after commissioning.

"Although the plant has been continuously optimized in recent years, we have now been able to significantly reduce our starch usage in the first few weeks with the help of OnEfficiency.Strength. The tool is very easy to use, and the operators are very motivated to integrate it into their daily work. We are confident that, in the future, savings can be increased even further. Now it is much easier to sustainably achieve the targeted quality at the lowest possible cost." (Fernando Vicente, Production Manager at PM 9 El Burgo)

OnView.MassBalance starts at an earlier point in paper production. The app's data maps the current stock flows in a diagram and depicts deviations from the standard. As soon as a defined threshold is exceeded, the application automatically highlights the relevant area in the diagram and recommends suitable courses of action to avoid fiber losses. In this way, OnView.MassBalance leads to targeted process optimization in stock preparation and provides the operating team with all relevant information if a different process setting is required. Both applications are integrated on Voith's OnCumulus platform. The platform provides users with an overview of all important process parameters, includes several industry-specific applications and also acts as a reliable and secure data repository. Building on the initial positive results, regular meetings are held between the Saica and Voith teams to jointly discuss progress, results and schedules. The goal is to further push the optimization of the system.

Juan Luis Mendoza, Digital Process Officer at Saica, explains how the new solutions have already opened up a whole new perspective: "The integration of OnEfficiency.Strength into the existing automation technology of PM 9 was seamless. This is now reflected in our very positive results. The digital tools support us in achieving our ambitious targets in an intelligent way."

For Mendoza, there is no doubt that the company will also implement Voith's Papermaking 4.0 solution on other machines in the coming years.

From Voith’s perspective as the technology partner, the balance of the project is thoroughly positive: "The solution we offered has proven itself and leads to resource important savings with qualitatively consistent results. Voith has clearly positioned itself as a reliable partner on the path to digitalization. This confirms our commitment to continuously advance our products in order to continue to be an innovation driver in paper production." (Renan Fusco, Head of Digital Solutions Sales at Voith Paper)