The world's largest drum pulper: Voith presents IntensaDrum Duo for production volumes of 3,000 tons of paper per day

News General news

- The new drum pulper IntensaDrum Duo processes 3,000 tons of recycled paper per day.

- The modular, two-part design makes it possible to enter new dimensions in pulping capacity.

- Maintenance and operating costs can be minimized while optimizing fiber quality.

The papermaking process starts with pulping and separation of coarse contaminants to prepare the pulp for the subsequent cleaning steps. Based on its many years of expertise, Voith Paper now introduces the latest technology within the BlueLine stock preparation – the IntensaDrum Duo, a two-piece drum pulper. The machine, suitable for recovered paper, is perfect for very high production volumes and is characterized by extreme robustness and high reliability and efficiency. The two-piece modular design corresponds to the IntensaDrum ID45XL, which has been used successfully many times for smaller production quantities.

Maximum robustness for large production volumes

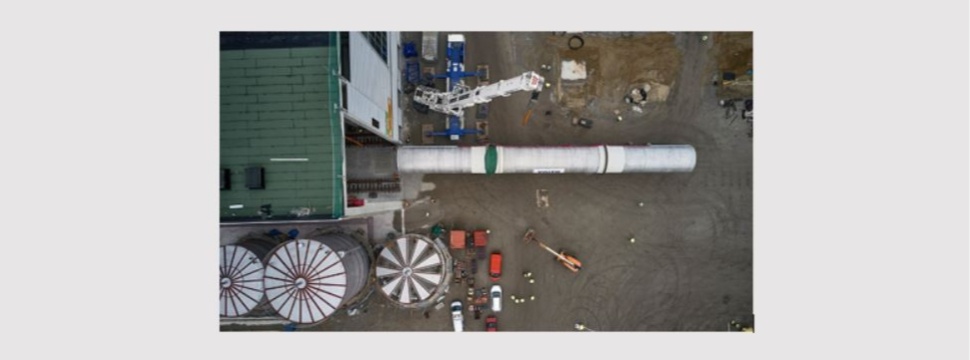

How well the machine concept works in practice is demonstrated by the installation of the IntensaDrum Duo at the company Progroup as part of the Taurus PM 3 project in Germany. With a diameter of 4.5 m each, the 48 m long drum pulper and the 23 m long screening drum have since then been processing 3,000 tons of recovered paper per day. The total length of the IntensaDrum Duo, which weighs over 300 tons, is 78 meters. This makes the stock preparation plant in the Taurus project the largest of its kind in the world.