Investment in the production of future-proof and sustainable packaging solutions: Voith acquires stake in Swedish start-up Yangi® AB

News General news

- Innovation and development partnership between Voith and start-up Yangi®

- Yangi® is leading the development of a dry forming process to produce 3D-formed, cellulose-based packaging in one machine line without process water

- Compared to the alternative energy- and water-intensive wet pulp molding process, the innovative process saves 75 percent energy

Voith has acquired shares in the sustainability start-up Yangi®, headquartered in Varberg, Sweden. Both parties signed the purchase agreement in December 2022. Yangi's® ground-breaking technology emerges from 10 years of R&D within its sister company, The Loop Factory®, which focuses on the megatrends of sustainability and circular economy. As a result, the leading full-line supplier Voith is investing in new, future-oriented technologies to further drive decarbonization in the paper industry.

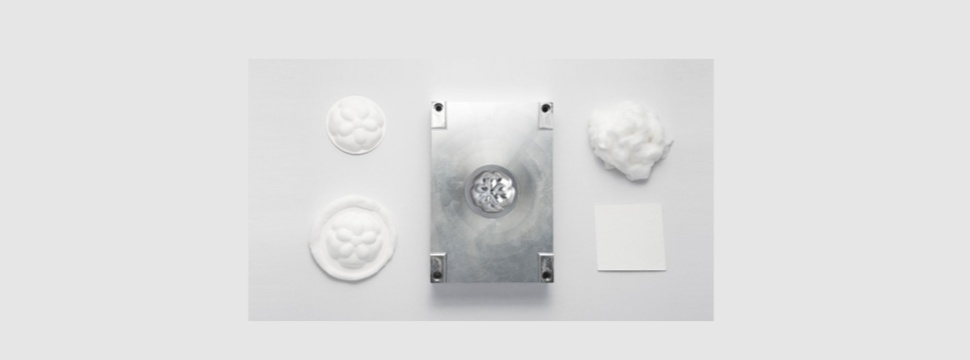

Yangi® has developed a manufacturing process and is pioneering a new technology to produce 3D-formed, cellulose-based packaging. The process is based on dry forming principles in one machine line and enables a cost- and resource-efficient solution that has the potential to replace rigid plastic at scale. Compared to the water- and energy-intensive wet pulp molding process, Yangi's® dry forming process uses no water and less energy, resulting in minimized CO2 emissions and 75 percent less energy consumption. The applications for packaging solutions are diverse and range from cosmetics and beauty products to fresh food, take-away, and consumer goods. For example, in addition to Voith, the luxury brand CHANEL has also acquired shares in Yangi® and is actively supporting its business development.

Compared to petroleum-based packaging, the newly produced fiber packaging saves 75 percent CO2 emissions. In addition, the innovative process is characterized by short cycle times.