Valmet receives the fifth order for an IQ quality control system for corrugator from Thai Containers Group in Thailand

News General news

Valmet is to supply a Valmet IQ quality control system for corrugator to Thai Containers Group's corrugated containers plant in Rayong, Thailand. The system will enable the plant to improve corrugated board quality and productivity and reduce waste caused by warped board. The start-up of the system is scheduled for the first quarter 2025.

The order was included in Valmet’s orders received of the first quarter 2024, and the delivery will take place in the fourth quarter 2024. The value of the order will not be disclosed.

The cooperation with Thai Containers Group started in 2020 with the successful implementation of the Valmet IQ quality management system at the Ratchaburi plant. After seeing the results, the customer has placed repeat orders for the Navanakorn, Orient Container, and Chonburi plants, making the current order for the Rayong plant the fifth one they have placed.

“We are committed to support our customer to improve the end-product quality and production efficiency. The customer wishes to produce flat sheet while avoiding post-warp and cracking in converting. With Valmet’s quality management solutions, we can help them achieve the set targets for the project and improve competitiveness,” says Thossapon Arunsaengsuree, Solution Sales Manager, Southeast Asia, Automation Systems, Valmet.

Delivery’s technical information

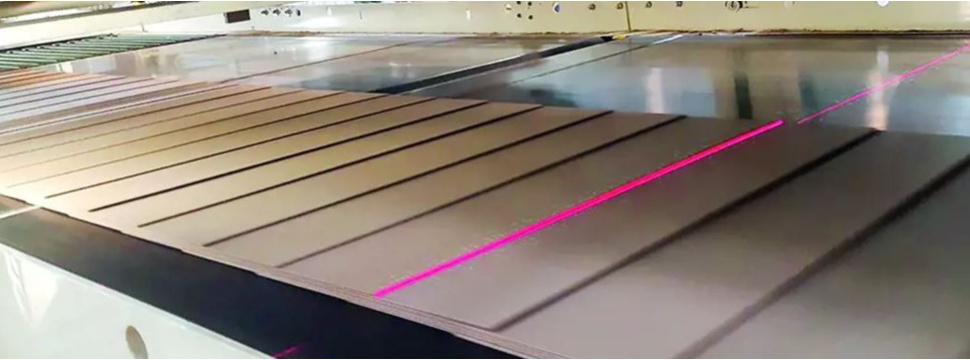

The delivery consists of a Valmet IQ Warp Measurement, a Valmet IQ Moisturizer with three spraybooms, a Valmet IQ Multipoint Moisture, Temperature Measurements and Microwave moisture measurement, which are integrated through automatic closed-loop controls.

Valmet IQ quality control system for corrugator combines online moisture, temperature, and warp measurements. It is used to control all corrugated board types to reduce sheet warping, improve bonding, and thus maximize corrugated board box plant performance. The moisture level control of the final product plays an essential role in eliminating corrugated sheet post-warping and cracking in converting.