Toscotec to supply a turnkey tissue line to Intertrade Hellas in Greece

News General news

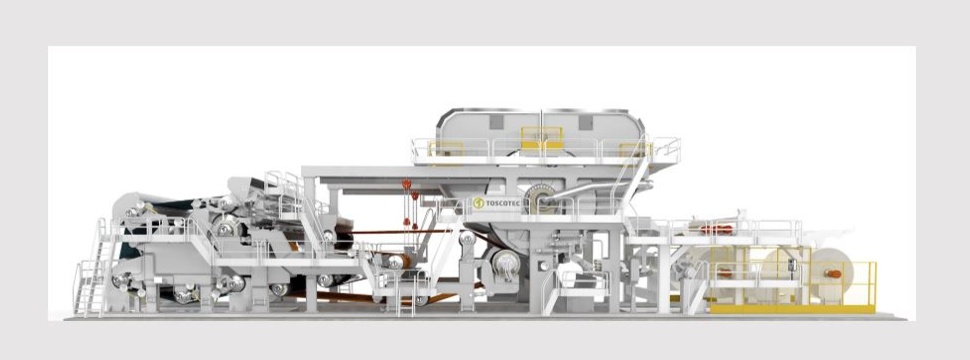

Toscotec will supply an AHEAD 2.2L tissue line on a turnkey basis to Intertrade Hellas at its Oyinofita mill, near Athens in Greece. The start-up is planned for 2026.

The new AHEAD 2.2L machine features a net sheet width of 5,600 mm, a maximum operating speed of 2,200 m/min, and a production capacity of over 80,000 tons/year. It is equipped with a fully hydraulic TT Headbox-MLT, TT NextPress shoe press technology, a third-generation design TT SYD integrated with the cogeneration system, and TT BulkyReel for optimal preservation of bulk and softness.

A customized Energy Package for maximum Energy Efficiency

Designed to maximise the energy efficiency of the entire production line, Toscotec’s tailor-made Energy Package is composed of TT TurboDryer, which uses the air system-recovered heat to lower water viscosity, enhance the shoe press’s de-watering action, and significantly increase post-press dryness. In the Yankee hoods, TT Swing delivers maximum flexibility and optimal energy efficiency by allowing an easy switch based on production needs from a parallel system (two separate circuits of heated air, one to the wet end hood and the other to the dry end) to a hybrid system (heated air to the wet end hood and only extraction from the dry end). TT Hood also features Toscotec’s automatic balancing system TT DryingEquilibrium, TT Hydrogen Burner which is equipped for the use of 100% hydrogen fuel in the future, and three steps of energy recovery.

Turnkey supply for the highest performance guarantees

The turnkey supply comprises the complete stock preparation system, Toscotec’s patented TT SAF® DD (Short Approach Flow system with Double Dilution) to reduce electrical consumption, the entire line’s electrification and controls including TT Brain DCS of upgraded design, wet-dust and mist removal systems, an air compressor station, roll handling and wrapping systems, and hall ventilation with conditioning system. The scope also includes one OPTIMA 2600 slitter rewinder fitted with automatic shaft puller and dedicated dust removal system. Intertrade Hellas also purchased a comprehensive service package with detailed engineering design, erection, training, commissioning, and start-up assistance.

John Delidimos, CEO of Intertrade Hellas, says, “We found in Toscotec the right technology partner to accelerate our growth in the market. Their strong background in turnkey operations was an all-important element because we are confident that they will successfully complete a complex tissue project such as this within the assigned timeframe. At Intertrade Hellas we value the most advanced and energy efficient technology to produce premium quality tissue for our consumers and customers.”

Alessandro Mennucci, CEO of Toscotec, says, “We are delighted to start a new partnership with an important group such as Intertrade Hellas. This new tissue line is state-of-the-art as it combines Toscotec’s top-of-the-line technology for energy efficiency with strong performances and flexibility.”

Matteo Giorgio Marrano, Toscotec Sales Manager, says, “We expect Intertrade Hellas to reap the fruits of this new AHEAD machine’s Energy Package right from the very start: on top of Toscotec’s well established energy efficient technology like the Steel Yankee Dryer and high-recovery TT Hood, our latest technological advances such as TT TurboDryer, TT Swing and TT DryingEquilibrium will really tip the scale in their favour when it comes to energy savings.”