Testliner: Everything About the Popular Liner for Corrugated Cardboard

News General news

Testliner is a special type of paper primarily used as a liner for corrugated cardboard. In the corrugated board industry, testliner has established itself as a popular raw material due to its properties and advantages. This guide clarifies the composition, production, and use of testliner.

What is Testliner?

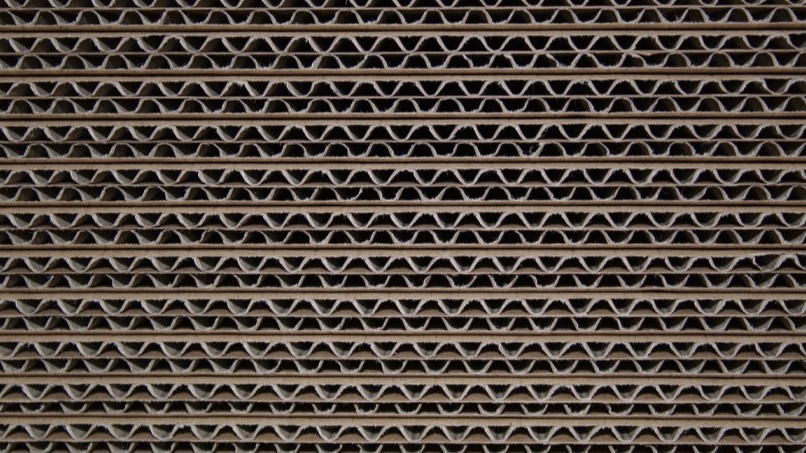

The term "liner" generally refers to the facing paper that serves as the inner or outer layer of corrugated board. Along with kraftliner, waste-based paper, and fluting, testliner is one of the most common raw materials for liners in Europe.

Testliner is a two- or multi-layered paper made entirely from recycled fibers, i.e., 100% waste paper. This makes it a cost-effective and environmentally friendly alternative to kraftliner, which is produced from virgin fibers.

Properties and Quality Grades

Depending on the quality of the waste paper used, testliner is divided into three grades in Germany:

- T1 - contains the highest quality recycled material

- T2 - consists of medium-quality recycled paper

- T3 - is made from lower-quality waste paper

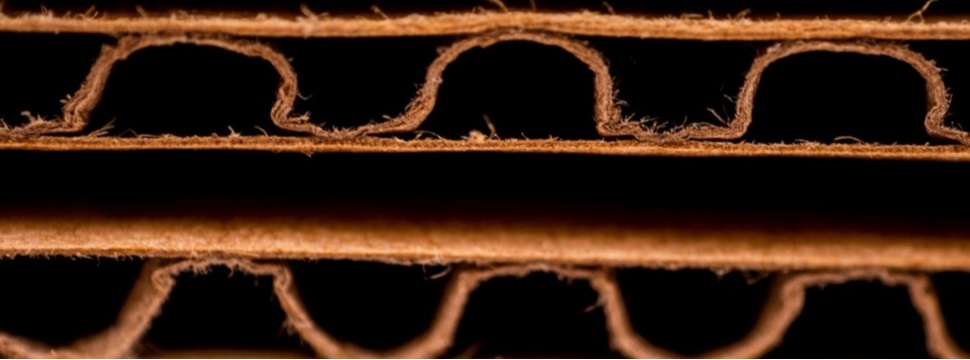

The grammage of testliner typically ranges between 100 and 200 g/m2. This makes it generally somewhat lighter and brighter than kraftliner. The fibers in testliner are shorter than in kraftliner, making it more flexible but also less tear-resistant.

Visually, testliner can be easily distinguished from other liners: It has a lighter color and a more structured surface than the uniform, often dark brown kraftliner. Waste-based paper made from unsorted waste paper, on the other hand, appears more grayish.

Use of Testliner

Testliner is primarily used as a base material for inexpensive corrugated board and cardboard boxes. The choice of the appropriate testliner grade depends on the requirements for the packaging:

T2 and T3 are suitable for light to medium-weight goods and shorter transport distances.

High-quality T1 testliner partially achieves the burst strength of kraftliner and can also be used for heavier, stackable boxes.

Due to its flexibility, testliner is sometimes also used as cushioning paper. Overall, the share of testliner in corrugated board production in Germany has increased to nearly 40% (as of 2010). It is mainly produced in Germany, other European countries, and to a lesser extent in the USA.

Advantages of Testliner

The increasing popularity of testliner has several reasons:

- In most strength values, testliner is equivalent to the more expensive kraftliner. Only for comparable burst strength, the surface weight must be slightly higher.

- As a recycled product, testliner conserves valuable resources and contributes to a sustainable circular economy. Packaging made from testliner is fully recyclable.

- Due to its production from waste paper, testliner is significantly cheaper than kraftliner made from virgin fibers. This enables cost savings in packaging materials.

- The lighter color and structuring give testliner a natural look that many consumers find appealing.

Conclusion: Testliner - Important Raw Material for Corrugated Board and Cardboard Boxes

Thanks to its economic and ecological advantages, testliner has established itself as an important raw material for corrugated board and cardboard packaging. By being made from 100% recycled paper, it conserves resources and is very affordable at the same time.

The various quality grades allow for a needs-based selection for different packaging requirements. High-quality testliner achieves similarly good strength values in many areas as the more expensive kraftliner.

For companies that value sustainability and cost efficiency, packaging made from testliner corrugated board is often the best choice. High-quality and environmentally friendly boxes are becoming increasingly popular with more and more consumers.