Sustainability meets efficiency: Sentrex chooses Mondi’s Advantage StretchWrap for pallet wrapping

News General news

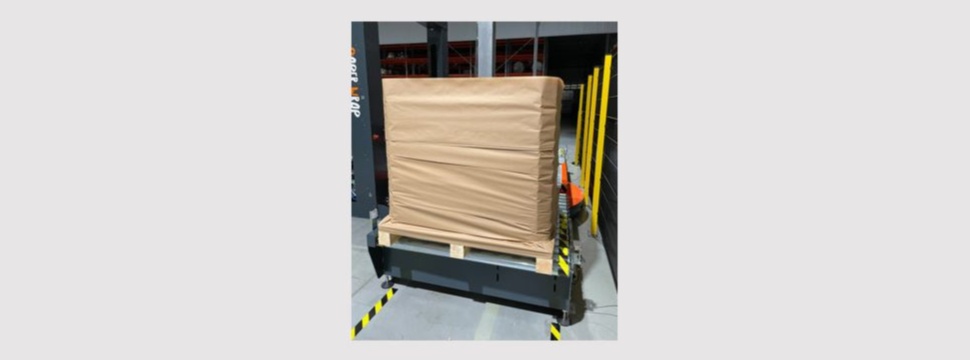

Mondi, a global leader in packaging and paper, has introduced its Advantage StretchWrap, a paper wrapping solution that replaces plastic stretch film and enables a more efficient logistics process, to Sentrex, a European manufacturer of paper bags.

Advantage StretchWrap is a fully recyclable kraft paper that is made from responsibly sourced materials. Mondi developed it to stretch and resist punctures, making it ideal for replacing the plastic stretch film that has traditionally been used for pallet wrapping and transportation. Advantage StretchWrap has 62% lower greenhouse gas (GHG) emissions when compared to virgin plastic stretch film, and 49% lower GHG emissions when compared to plastic film made with 50% recycled content, according to a peer-reviewed independent life cycle assessment.*

By switching to Mondi’s kraft paper solution and using EW Technology’s fully automated machinery, Sentrex was able to increase efficiency in the wrapping process: The production of the paper bags requires a drying process to remove moisture from the bags before they can be wrapped in plastic stretch film, to avoid condensation within the packaging. Mondi’s Advantage StretchWrap is breathable and can therefore be used to wrap and pack products immediately after paper bag production within one in-line process.

The larger dimensions of the Advantage StretchWrap reel mean that a new reel is only needed every 400-600 pallets compared to every 40-60 pallets for plastic wrapping. The paper solution can be used to wrap different shapes and sizes of pallets and cover the gap between the pallet and the product, providing good stability and safety during transportation.

Michał Nogielski, Technical Director at Sentrex says: “We are fully committed to using Mondi’s paper wrapping solution at scale, as part of our ongoing commitment to seeking out and using the most sustainable business practices throughout our operation. The teamwork between ourselves, Mondi and EW Technology meant that the whole adaptation process was swift, and the new wrapping machines and reels are running so successfully that we are delighted to recommend this to our own customers, for instance for pallet wrapping dry food products such as flour and sugar.”

"This change means that Sentrex can wrap their products in more sustainable packaging, work towards a more circular system and make a positive contribution to the environment. Additionally, the packaging sequence is more efficient due to the possibility of wrapping the pallet immediately after production, without the need for seasoning the paper bags. The collaboration with Sentrex is living proof that our Advantage StretchWrap solution is not limited to business-to-consumer applications but brings value to leading industry players in the business-to-business sector." (Jan Murzyn, Business Development Manager Speciality Kraft & Functional Paper at Mondi)