Run-up phase for the PM3 paper factory picks up speed: Monthly record of over 50,000 tonnes achieved

News General news

Progroup's PM3 paper factory is again setting new records. The hightech paper machine is currently still in the run-up phase. It is consistently producing outstanding production figures. In January 2021, it achieved another important milestone with a record production output of over 50,000 tonnes.

The run-up phase continues to proceed as planned. Additional fine adjustments will continue to improve the production output so that ultimately PM3 will produce up to 750,000 tonnes of containerboard made entirely from recovered paper each year. Progroup is thus increasing its production of containerboard from 1.1 million tonnes to a total of around 1.85 million tonnes annually. As one of three paper factories that the company now operates, the new plant forms an important part of Progroup's consistent growth strategy.

“By increasing our paper production capacity, we will continue to be able to offer our customers the certainty of having a stable supply of the raw material they need. We will thus remain a strong and reliable partner to our paper and corrugated board customers,” says Progroup founder and CEO Jürgen Heindl.

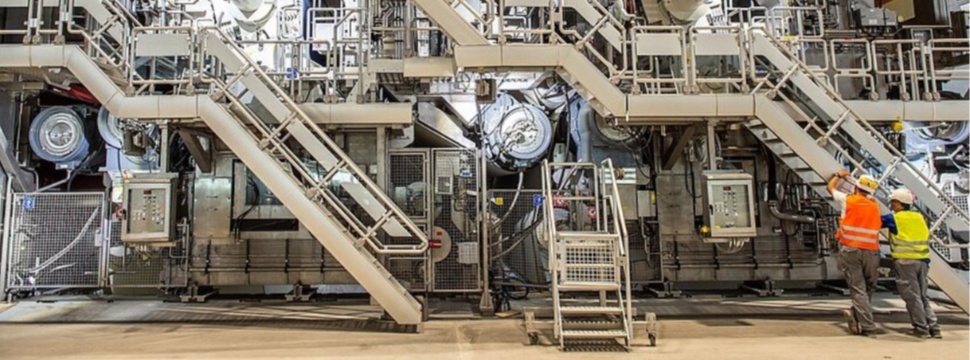

Successful innovation leadership makes PM3 the benchmark in the industry

Innovation leadership is an important aspect of Progroup's corporate strategy. It is based on consistently developing existing processes, technical innovations and cooperating in a spirit of trust with partners from industry. Plants such as PM3 therefore not only lead the way when it comes to sustainability, but also set the technological benchmark within the industry.

For example, as well as having one of the world’s most powerful recovered paper processing facilities, the paper factory has a circulating water treatment plant with a closed water cycle. This state-of-the-art technology ensures that process water is cleaned and reused in a closed loop. As a result, Progroup saves around 80 per cent or 3,750,000 cubic metres of fresh water per year and makes a clear statement in an era of climate change.