Pixelle Invests $1.4 Million in Mill Safety and Productivity with Industry First Robotics

News General news

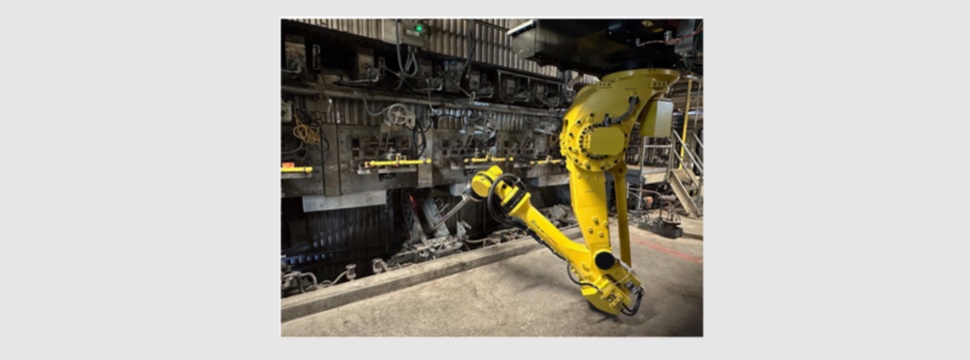

Robotic equipment cleans recovery boiler spouts without manual intervention

Pixelle Specialty Solutions (“Pixelle”), a leading manufacturer of specialty papers in North America, has improved safety and productivity at its Spring Grove, Pennsylvania facility by installing a smelt spout robot manufactured by Valmet.

The smelt robot is essential for keeping recovery boiler spouts open and improving efficiencies in the liquor recovery cycle. The first smelt robot installation of its kind in North America, the robot regularly cleans the recovery boiler smelt spouts ensuring stable smelt flow, optimum cleaning and safer boiler operation, without manual intervention.

“We’re proud to introduce the industry-first smelt robot installation in North America, supporting our ongoing commitment to operational excellence and innovation in specialty papers,” said Ross Bushnell, President and Chief Executive Officer, Pixelle. “By leveraging the latest automation technology, we are positioned to drive greater mill safety, productivity and quality.”

Removing smelt deposits from recovery boiler spouts is a critical task in maintaining boiler reliability, but manual processes can put operators in close proximity to molten smelt, black liquor, hot gases and ash. Instead of an operator manually removing smelt deposits, the robot cleans all spouts safely and efficiently in a carefully programmed sequence. Operators retain control and visibility remotely, programming cleaning sequences and using the robot’s camera for troubleshooting and evaluation.

“The heart of an integrated pulp and paper facility is a recovery boiler, and removing smelt deposits from its spouts is a challenging and time-consuming maintenance task,” said Jeff Forry, Director Pulp and Utilities, Pixelle. “Our new smelt spout cleaning robot will keep spouts clean, protecting our people and allowing operators to focus on other critical tasks.”

The six-servo motor, FANUC M-900 series robot was designed, manufactured and installed by Valmet, a leading developer and supplier of technologies, automation and services for the pulp, paper and energy industries.

“It’s incredibly exciting for Valmet and the paper industry at large, to install the first smelt spout cleaning robot system in North America at Pixelle’s Spring Grove, PA mill,” said Drew Humphries, Vice President, Pulp & Energy, North America, Valmet. “By helping Pixelle reach new levels of safety and boiler performance, this industry first project will help change perceptions about what is possible in pulp and paper.”