Pesmel delivers automated warehouse solution to Stora Enso’s Oulu mill

News General news

The fully automated high-bay warehouse solution is a part of Stora Enso’s EUR 1 billion investment to convert the remaining idle paper machine at the Group’s Oulu site in Finland into a high-volume consumer board production line. The warehouse is expected to be in operation in the spring of 2025.

Pesmel’s delivery includes a 40,000-ton automated high-bay warehouse with transfer cars and joint conveyors for board rolls. The system works as a distribution center between two production lines and the port operator. The warehouse receives rolls from production and organizes them automatically into the right shipment batches. The majority of the production is shipped as sea freight via a deep-water harbor located next to the mill. The remaining rolls are transported by trucks or train to their destination.

“Fundamental to Pesmel’s automated warehouse solutions are high handling capability and flexibility. It is easy to integrate into the mill’s material flow and the footprint of the warehouse is smaller compared to other solutions, an important factor in confined mill and harbor areas,” states Kaj Fahllund, Vice President, Pulp & Paper from Pesmel.

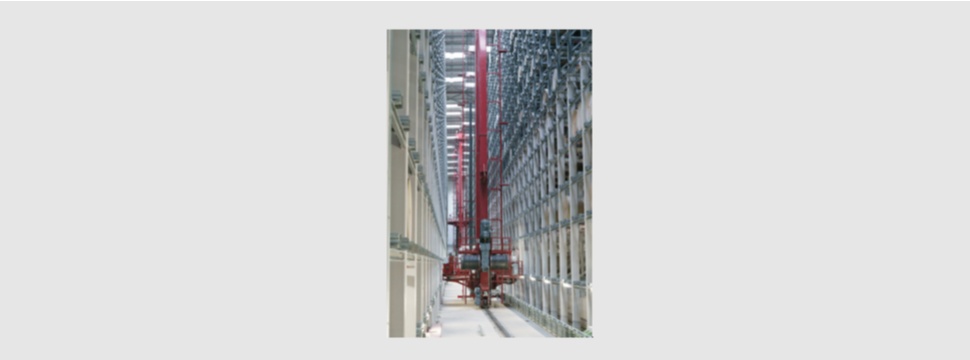

In high-bay warehouses the rolls are stored up to 35 meters high

Pesmel will also deliver a Warehouse Management System (WMS) that controls all material flows and shipping functions within the warehouse. The system identifies every roll and automatically organizes the shipments according to the orders. The WMS enables smooth sorting and out-feeding of rolls with high volume, which shortens the turnaround times of ships and trucks considerably.

”We have been developing our own software for these types of needs for the last 15 years. This enables smooth integration of equipment with upper-level data management system without external interphases,” concludes Fahllund.