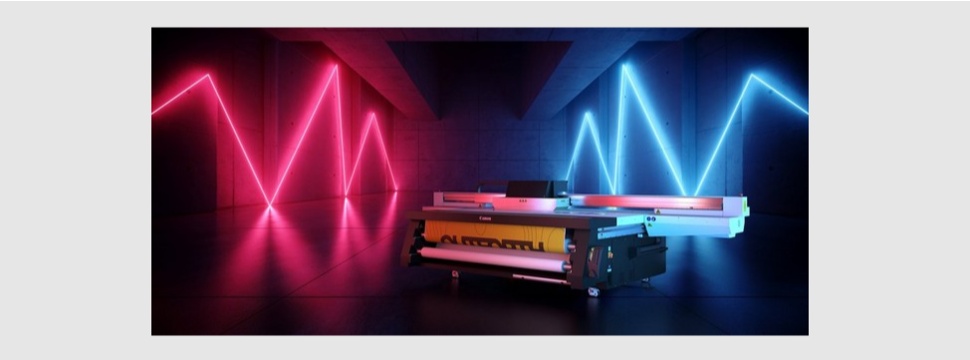

Canon Extends World-Leading Arizona Flatbed Printer Family with Arizona 1300 Series Including FLOW Technology

News General news

Canon launches two new models in the Arizona 1300 flatbed printer series, the GTF and XTF, featuring award-winning FLOW technology, an innovative zone-free vacuum system that makes media handling easy.

Extending the comprehensive Arizona flatbed printer family, the Arizona 1300 series with FLOW technology serves the growing mid-volume segment, enabling large format graphics printers and other print service providers (PSPs) to offer their customers an extensive range of applications for retail, signage, interior décor, packaging, and industrial markets. Designed with productivity in mind, the new printers provide versatile, accurate and highly efficient multi-board and double-sided printing.

With variable print speeds of up to 52.8 m2/hr, the Arizona 1300 series with FLOW technology allows users to print pin-sharp, high-value print applications. Customers will benefit from eye-catching prints on rigid or flexible media of any size up to 1.25 x 2.5 metres with the Arizona GTF or 2.5 x 3.08 metres on the Arizona XTF. Thanks to FLOW technology it is much quicker to change media and board size, making it the ideal solution for printing many short-run jobs spread throughout the day, allowing users to deliver commercial quality prints with higher levels of productivity. Since there are no vacuum zones, far less masking and taping is required, reducing effort, time and cost.

Automation enhancements for industrial productivity

The Arizona is designed to be low maintenance with automation enhancements that provide users with the capabilities to support industrial productivity standards and features to improve uptime, essential for today’s print businesses. These include an updated, hands-free, printhead maintenance system that selectively restores nozzle function in seconds and a user interface updated with Advanced Image Layout Controls. The new, last-minute pre-print adjustment capabilities include trimming, multi-reference points flexibility, and visualisation and modification of the print layer sequence. These controls also allow operators to make last-minute substrate choices needed to respond quickly to changes in board material availability, helping to use up leftovers and reduce waste while providing more flexibility, time savings and cost efficiencies. The Arizona 1300 series with FLOW technology also includes an accounting interface (API), providing valuable data about ink consumption and production time, for example, for further processing in accounting packages.

Exceptional print quality on an array of rigid and flexible media

New print modes have been added for the Arizona 1300 series with FLOW technology. These include Quality-Smooth, Production-Plus and Quality-Plus (available for 8-channel configurations), which provide exceptional print quality, print after print. The additional ‘Plus’ modes also allow users to achieve a larger colour gamut to create eye-catching applications with light cyan, light magenta and white inks in the higher-quality print modes for exceptional quality photo and fine-art applications.

The new Arizona 1300 GTF and XTF models retain the award-winning, third generation VariaDot printing technology which delivers photorealistic image reproduction and an even more advanced use of different ink drop sizes in the various colours ensuring the biggest choice in quality and speed ratios. Print providers can now offer high-quality applications across an array of rigid and flexible media — as well as irregular-shaped substrates — more easily and more productively.

Sustainable by design

The product lifecycle of the Arizona flatbed printer series, from design and manufacturing to use, reuse and recycling, has been developed to be sustainable. Blower boxes for creation of the FLOW and LED curing bring energy efficiencies, while it is designed to be repairable and easily disassembled - enabling reuse and recycling of materials and supporting the transition to a circular economy. In addition,100% renewable electricity is used to produce the devices at the manufacturing site in Germany and VariaDot technology reduces ink consumption. GREENGUARD Gold certified, the inks are safer for use in public environments and are free from Hazardous Air Pollutants (HAPs) and Volatile Organic Components (VOCs).

Mathew Faulkner, EMEA Director, Marketing and Innovation, Wide Format Printing Group, Canon Europe says: “Having launched the first Arizona flatbed printer 17 years ago, we’re building on a solid foundation with our world-leading flatbed printing technology to support the growing mid-volume segment of the market and respond to print buyer demand for faster turnarounds - and we’re now expanding the Arizona 1300 series with FLOW technology. With the added FLOW technology and automation enhancements, these new models deliver the proven Arizona quality and versatility, but make production quicker and easier than ever, boosting our customers’ competitiveness.”

Commenting on their experience of using FLOW technology with the Arizona 2380 XTF, Jens Filipsson, Owner of Wiking Reklam, based in Sweden, explains, “Installing the Arizona 2380 has enabled us to increase our productivity by up to 30% because, with the FLOW technology, we no longer have to rely on manual intervention to mask the table. The software just simplifies everything. This increase in efficiency allows us to deliver products on time, every time. The high-quality output from the Arizona 2380 perfectly matches the standard we look to achieve across all jobs. The technology also gives us a lot of flexibility and if we didn’t have this solution in place, we wouldn’t be able to remain competitive. We’re really pleased with our latest investment and look forward to continuing our long-standing partnership with Canon.”

Elevated printing up to 2mm

Also available with the Arizona 1300 series with FLOW technology is the new PRISMAelevate XL software, enabling customers to design creative, high value applications with tactile elevation effects by creating textured surfaces, embossing, metallic accents and raised lettering up to 2mm. PRISMAelevate extends the powerful PRISMA XL Suite and succeeds the Arizona Touchstone software - delivering twice the elevation at up to 20% higher speeds on the world-leading Arizona 1300 and 2300 flatbed series.