Improved sludge dewatering at Metsä Board Simpele

News General news

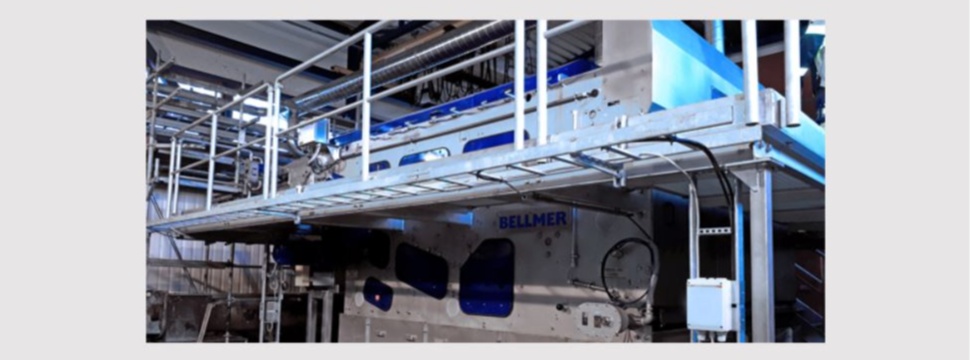

Metsä Board is a leading European producer of premium virgin fibre paperboards and also a frontrunner in sustainability. The Metsä Board Simpele paper mill, founded in 1896, is located in south-eastern Finland on the border with Russia. The production of premium lightweight folding boxboards and food service boards are just as much a part of the product portfolio as white kraftliners for consumer goods packaging. The sludge from the production process is sent for incineration. In order to achieve the highest possible final dry content before this step, Metsä Board Simpele installed a WinklePress WPI 4 last year. The decision to go with Bellmer Separation Technology came after proven results through on-site pilot tests.

The concept of the WinklePress, with up to 5 dewatering stages, is particularly suitable for a slow and gentle pressure build-up. The WinklePress is equipped with a high-pressure press zone to optimally dewater the sludge consistency from the production process. Furthermore, the closed stainless steel frame makes it resistant to corrosion.

During project execution, the tight schedule for the production shutdown had to be strictly adhered. The Corona pandemic also hampered project implementation. Nevertheless, the cooperation between the project teams from Metsä Board and Bellmer was excellent. The timing was kept well within schedule and the WinklePress was commissioned during the 4th quarter of 2020.

The final dry content increased by more than 5%, depending on the type of sludge, to up to 30% TS while a smooth 24-hour operation significantly improved overall sludge treatment in Simpele.