ANDRITZ to supply VIB moisturizing technology for Xianhe Group in Hubei Province, China

News General news

International technology group ANDRITZ has received an order from Xianhe Co., Ltd., in Hubei Province, China, for the supply of VIB moisturizing technology for two new paper machines.

The plants will supply 300 t/day décor paper with a machine speed of 1,000 m/min and a paper width of 3,860 mm. The equipment installation is expected to be completed during the second half of 2023.

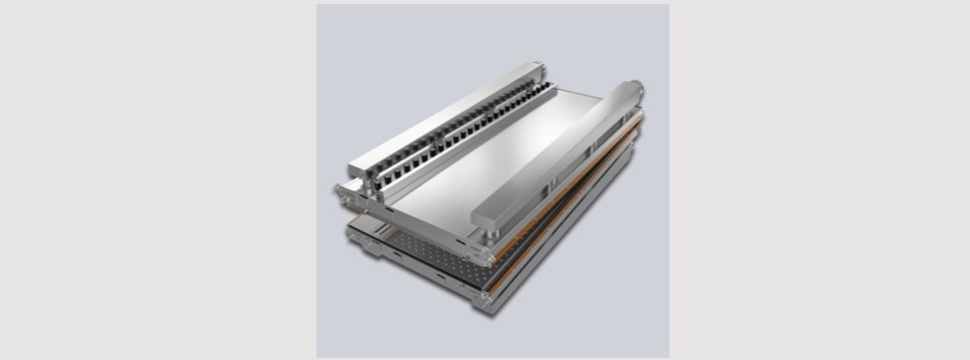

The air water spray will be installed below the last cooling cylinder to increase the paper moisture up to 3.5% with a 2-sigma value below 0.1%. The VIB MoistureTech will be installed before the machine calender to ensure highest paper quality standards. Precise steam application and the unique design comprising dwell zone provide best paper parameters for efficient calendering. The VIB MoistureTech is not only used for decor paper but also for conditioning and curl control on laminated grades and silicone papers.

The scope of supply also comprised spray boom with 80 nozzles, air and water supply, edge trim control, VIB MoistureTech with 2 x 30 zones, steam supply including desuperheater system as well as the corresponding CD control hard- and software and control cabinets. ANDRITZ will execute installation supervision, start up and performance optimization.

During the last decade, ANDRITZ has already supplied VIB technology successfully for several paper machines of Xianhe Group. Considering the experience with ANDRITZ VIB this new order placement was corollary to strengthen the long-lasting partnership between ANDRITZ and Xianhe Group.

As a world market leader, ANDRITZ offers steam-profiling solutions for the entire paper machine and paper moisturizing technology to improve the sheet’s cross-directional moisture profile.

Xianhe Co., Ltd. is the leading enterprise of specialty paper in China and one of the largest enterprises in the research and development and production of functional materials in China. It has the production capacity of the whole industrial chain including forest land, chemical industry, pulp making, energy, logistics, and paper products. The company invested 10 billion RMB in Shishou, Hubei Province with an annual output of 2.5 million tons of pulp and paper, so called "high-performance new material recycling economy" project.