Altonaer Wellpappenfabrik with further state-of-the-art investments

News General news

The Altonaer Wellpappenfabrik GmbH & Co. KG, based in Tornesch (near Hamburg) and part of the Panther Group, will continue to invest in productivity and capacity following its investment in an additional rotary die cutter at the end of 2020.

In spring 2021, the entire finished goods palletizing system will be replaced. As the semi-finished goods warehouse was already fully automated throughout the plant in 2019, the renewal of the palletizing system will now enable end-to-end digitization of the entire workflow in the company.

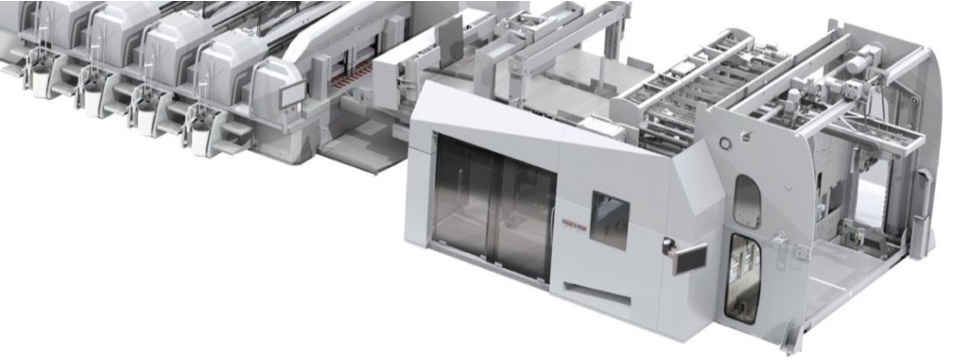

In the second half of 2021, an additional high-performance inline machine will then be newly installed. This will lay the foundation for further growth in the folding box sector as well, as the fully automated 4-color machine will further increase the productivity level. Among other things, it is equipped with a die cutter, which is used, for example, to cut out handles for moving boxes, and has an error ejection module and camera monitoring. A prefeeder and a robot take care of the loading and unloading of this high-performance machine.

This enables Altonaer Wellpappenfabrik GmbH & Co. KG can produce four-color, precisely fitting, attractive folding boxes very productively in a single pass.

This investment offers the possibility to meet customer requirements, such as highest quality and capacity. It will also improve energy efficiency and further reduce CO2 emissions per package.

With these measures from 2020/21, Altonaer Wellpappenfabrik is again investing over 10 million euros in quality and productivity in order to remain the leading corrugated board company in northern Germany.